RKM Poly Vee Disc Return Roller – Reduce Carry Back

Low Frictional Resistance

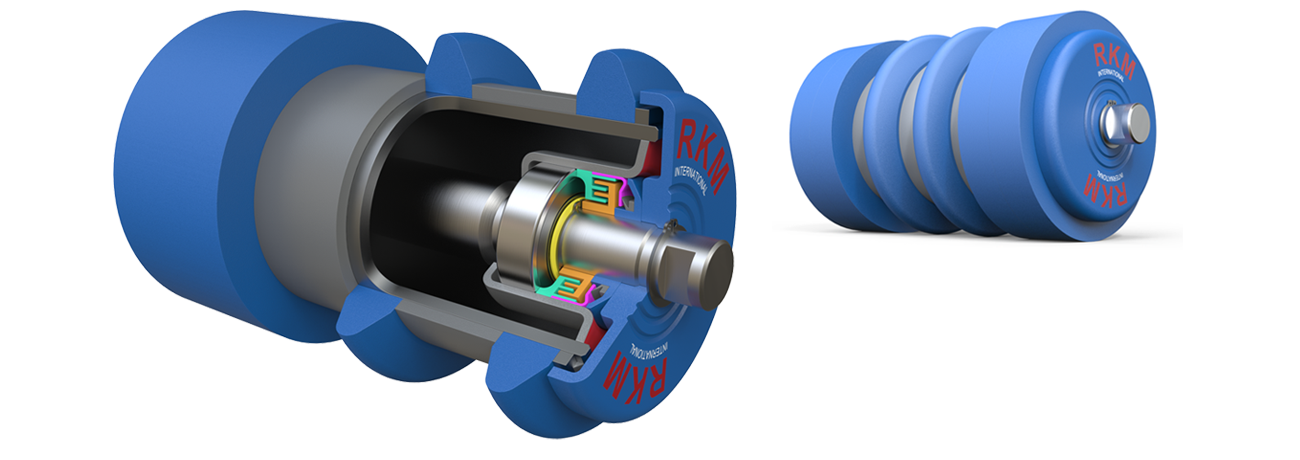

The RKM Poly Vee Disc Return Roller is a proven performer when it comes to dealing with carry back issues in materials handling environments such as coal, iron ore and grain. The discs are available in two different profiles, with the rounded profile used on the centre disc and the square profile used on the outer discs to prevent belt hang up if a belt becomes misaligned during operation. Quality construction, triple layered sealing package and additional outer cover make the RKM Poly Vee Disc Return Roller a great option when looking for a more durable and hard wearing alternative to rubber. The roller is also available with an extensive list of product upgrades to meet your specific operating conditions.

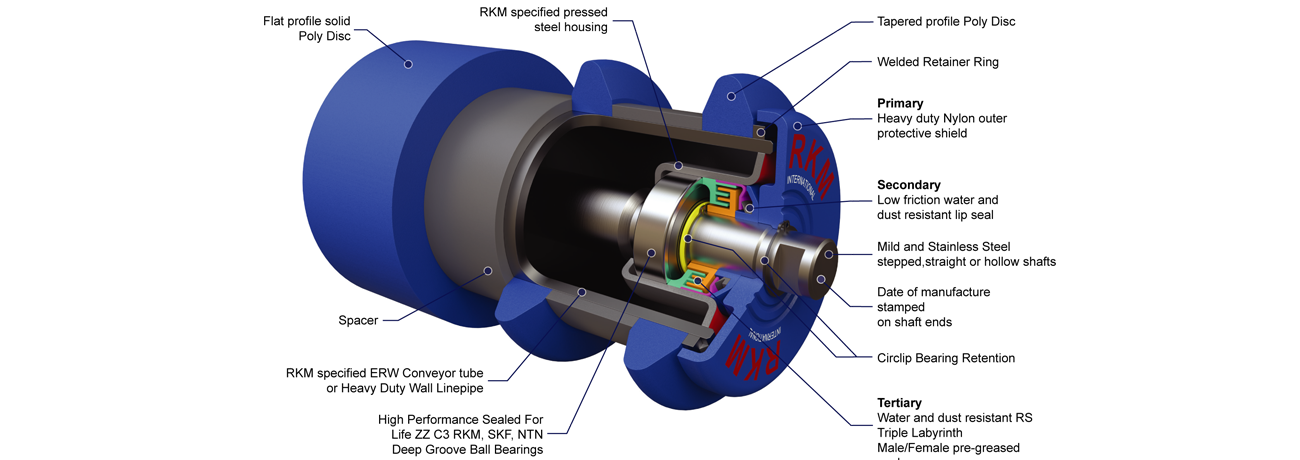

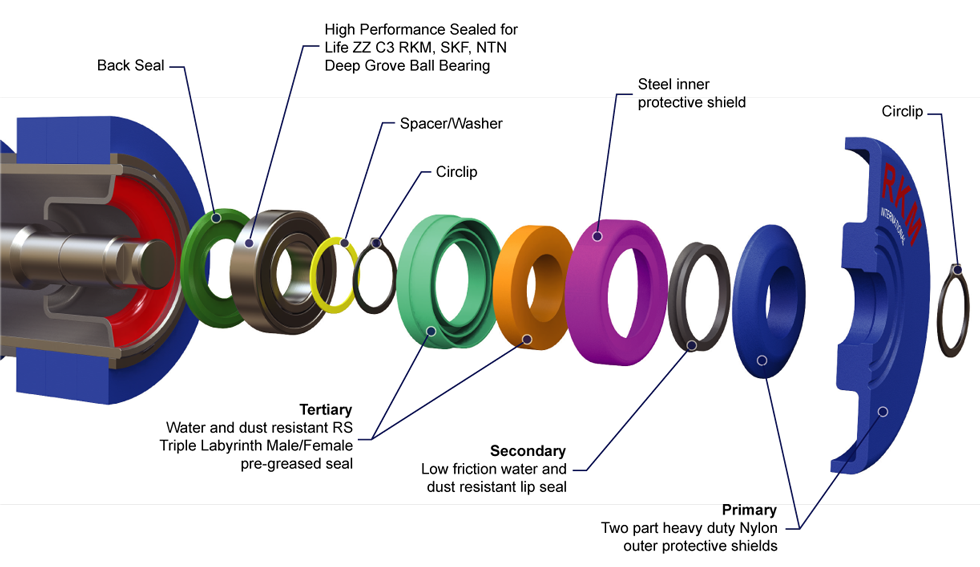

Seal Package

- Industry proven performance

- Large outer shield for extra rock jam protection

- 3 layers of bearing protection preventing the ingress of foreign material

- Optimal balance between sealing protection and low frictional resistance

- Water & dust resistant

- Bearing end float adjusted to meet your specifications

Roller Assembly

- Balanced to ISO 1940-1:2016-G40

- Reduced roller surface area, which helps shed material build up on the roller surface and prolongs roller life

- 2 x disc profiles. Flat discs are used on the ends and tapered discs in between. The flat discs reduce wear issues when the belt is tracking across the roller face

- Press fitted poly discs and welded end retainers ensure positive retention during operation

- Excellent abrasion resistance

Upgrades

- FRAS Rubber

- FRAS Seals

- Hollow Shafts

- Name Brand Bearings

- RKM Smart Idler – Live Roller Monitoring

- Reinforced Bearing Housings